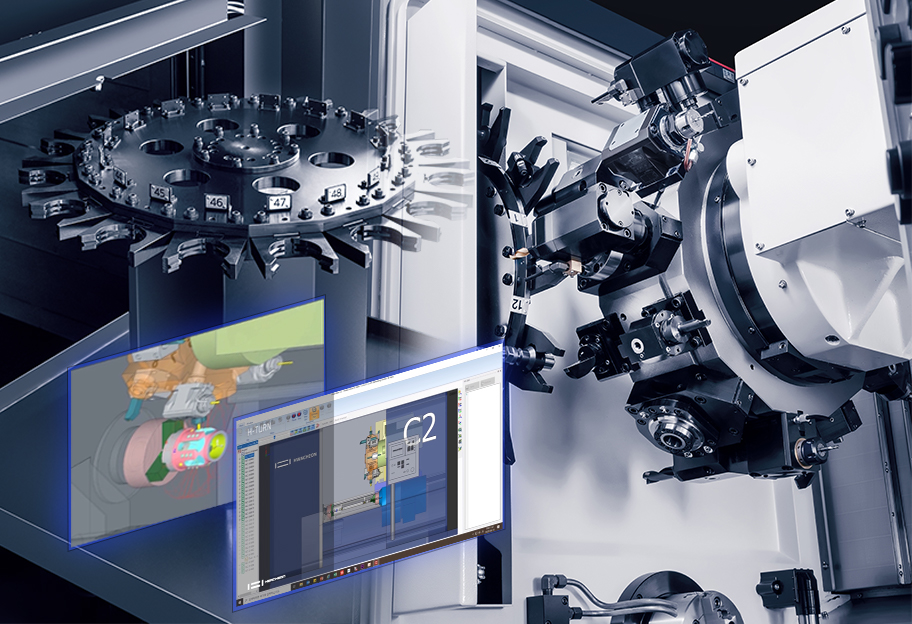

ATC for Turning

Automatic tool change functions are provided for turning center products.

Unexpected interference due to tool change can be checked by pre-simulation.

Let me introduce you to five machining solutions in Hwacheon.

ATC for Turning

Automatic tool change functions are provided for turning center products.

Unexpected interference due to tool change can be checked by pre-simulation.

Details of the Solution

HWACHEON Turning Solution by Magazine

HWACHEON Vertical Turning Center Line-up with ATC

Automatic turning tool change is available for vertical turret type T/C such as, VT-650, VT-950+, VT-1150+,

For RAM type large vertical T/C VT-2000 is able to change various tools such as milling tools & angle head automatically.

HWACHEON Integrated Multiplex Turning Center C1/C2 with ATC

Turret type Horizontal T/C with ATC for turning tools as well as milling tools.

It is capable to manufacture parts in complex geometry which require many tools with a single chucking and ATC solution.

HWACHEON Lathe Interference Check Simulation Software ‘H-TURN'

This software is for safer machining of parts of complex geometry. In case of using ATC,

unexpected interference of tool change can be checked through this simulation software before machining.

Product Variation

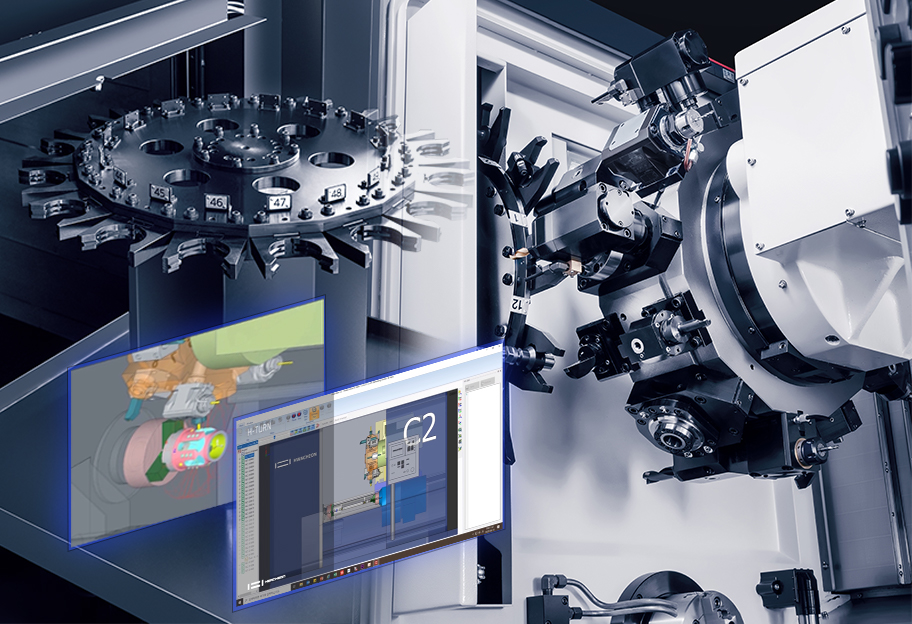

Sheer Turning

Rigid frames and process-control software packages contribute to more precise results for long or hard workpieces, which often present trouble in machining.

Details of the Solution

HWACHEON Turning Solution for High-precision Turning

High-rigidity Mechanical Structure Faithful to the Basics

High-precision turning is achievable by implementing a heavy duty cast iron frame & large-diameter ball screw.

-. Minimizes deformation of work piece, even long shaft machining.

-. Turning of hard material with high surface quality

Improvement of Machining Performance through Process Control Software

-. HLVC : Suppresses chattering when machining long material

This Software avoids excessive vibration by changing the RPM of the spindle when chatter is detected.

Recommended for customers who;

1) want to machine long material above L/D=10

2) want to machine long inner diameter above L/D=3

3) want to machine long grooves above L/D=3

-. L-HTDC : Lathe-HWACHEON Thermal Displacement Control System

Improves machining precision through real time thermal displacement correction according to the temperature variations in frame, coolant and room temperatures.

-. L-HTLD : Lathe-HWACHEON Tool Load Detect System

Monitors the tool wear in real time to prevent accidents and collisions that may result from worn or broken tools.

This feature allows for longer tool life and better part finishes as well.

Product Variation

CUTEX-180

6-8” Horizontal TC

Hi-TECH 230

8-10” Horizontal TC

Hi-TECH 450

10-15” Horizontal TC

Hi-TECH 750

18-21” Horizontal TC

Hi-TECH 850

32” Horizontal TC

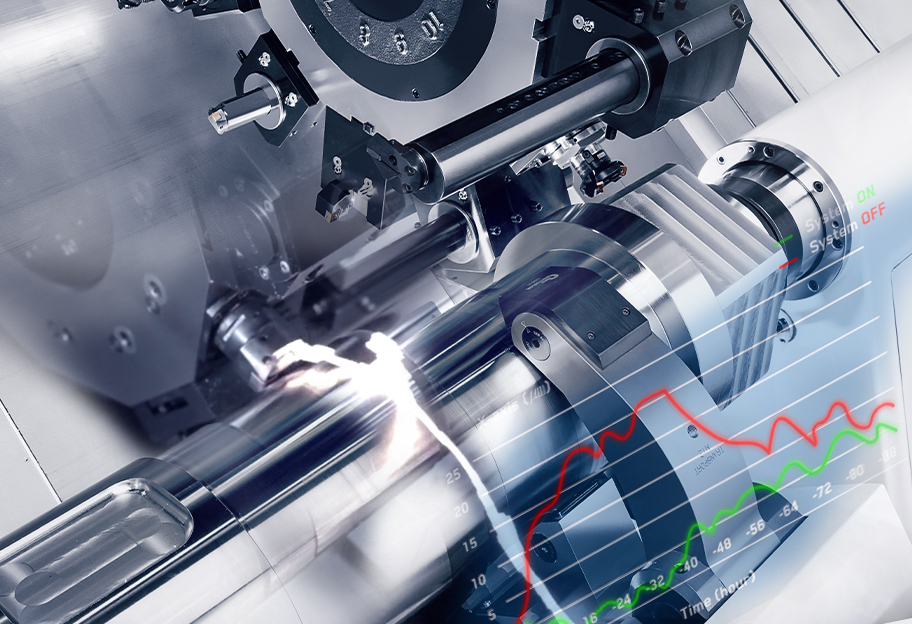

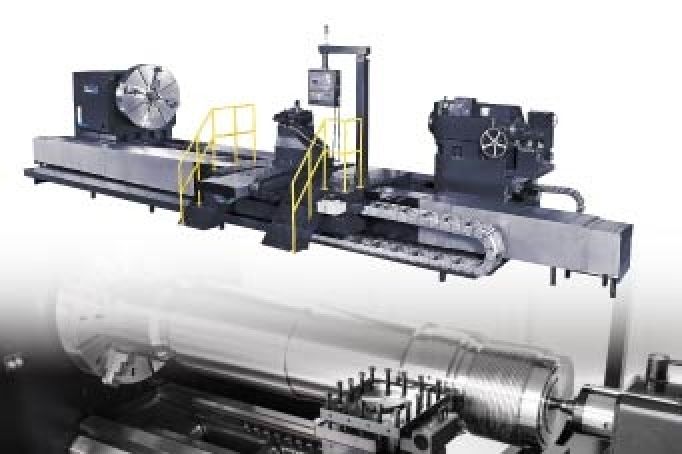

MEGA-ll Series

Huge Duty CNC Lathe

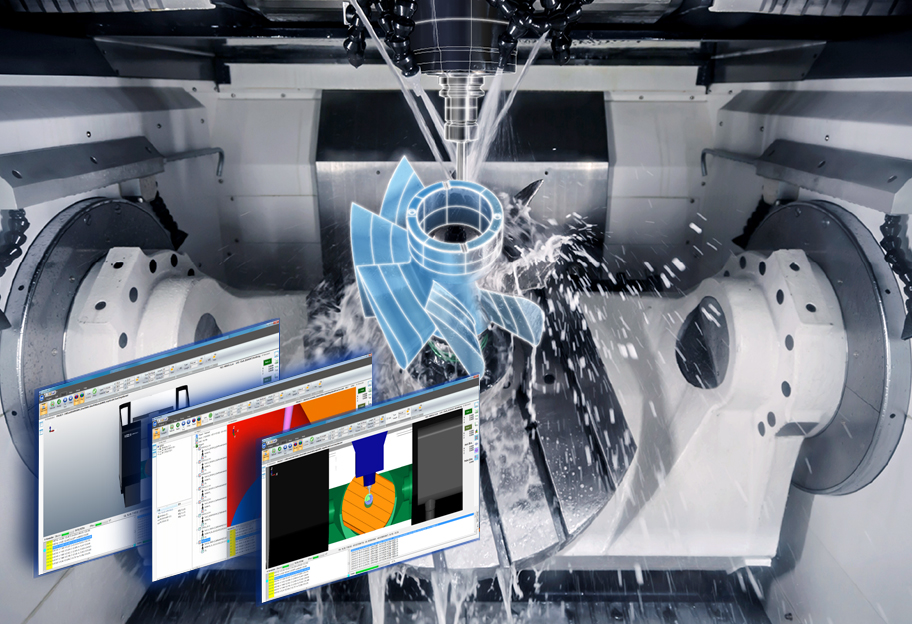

5-Axis Solution

Provides HWACHEON’s unique software and hardware integrated solution for high precision 5-axis machining of complex parts.

Details of the Solution

HWACHEON’s Optimized Solution for 5-Axis Machining

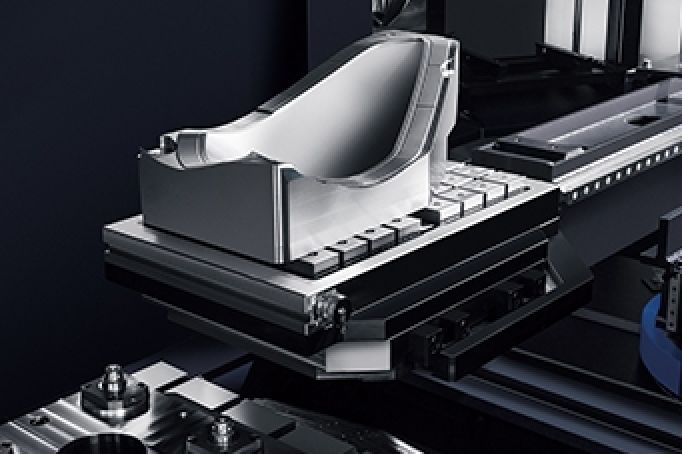

5-axis machining centers are mounted with high-precision, high-rigidity rotary tables and universal heads made with HWACHEON's own technology. The 5-axis machining centers specialize in manufacturing molds or parts that require complex, high precision machining.

A wide variety of parts and materials can be machined efficiently through various spindle options. Even higher precision machining is possible through HRCC, an optimized software for calibrating and compensating of the rotation center and rotation axis and errors in the rotation axis.

H-SIMUL 5X, a real time synchronized simulation software for interference checking, is provided for safe 5-axis machining.

HWACHEON Product Video : D2-5AX

Product Variation

H-SIMUL 5X

5axis Simulation SW

SIRIUS-2500/5AX

Head Tilting 5-Axis

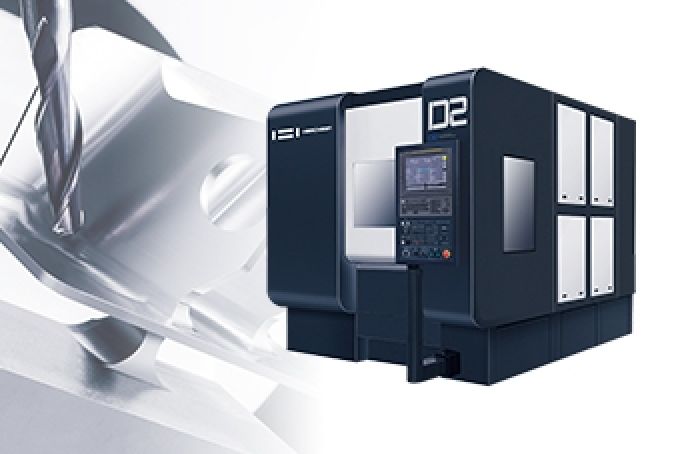

D2-5AX

Ø600 Table 5-Axis

M2-5AX

Ø500 Table 5-Axis

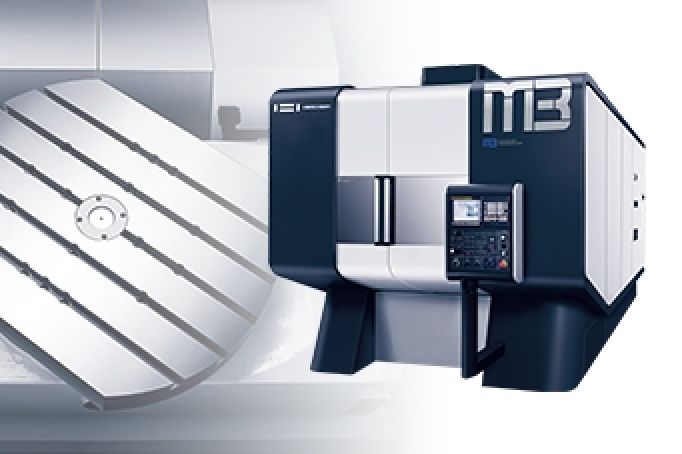

M3-5AX

Ø700 Table 5-Axis

M4-5AX

Ø800 Table 5-Axis

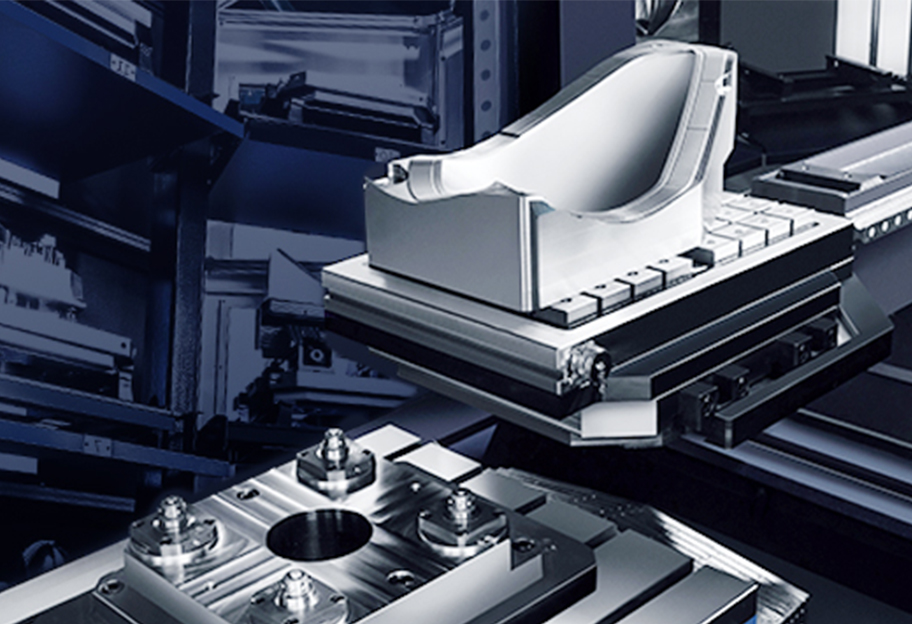

Automation Solution

Provides automation solutions optimized according to customer requirement by various types of automation systems.

Details of the Solution

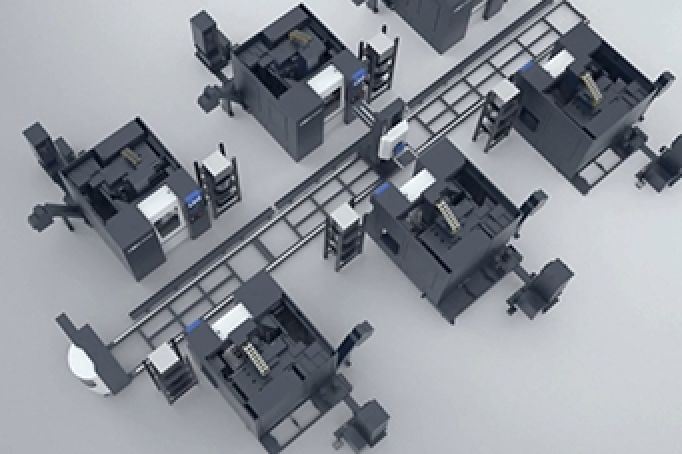

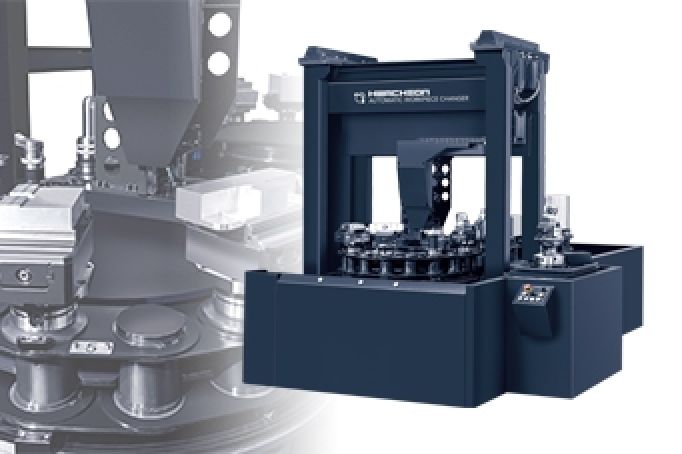

Optimal Automation Solution for Improving Productivity

To cope with various sizes, types and conditions of the work, we have a variety of product lineups ready, pallets and workpiece changers are available from smaller(80kg) to larger(20ton).

In order to provide an automated system optimized for the customer's site, single or multiple automation systems can be integrated and operated in various arrangements, such as circle type or matrix type.

In addition, we provide an automation system using robots that can produce multiple processes in one-stop.

HWACHEON Product Video : HMP-700

Product Variation

HMP-700

700kg Pallet System

HMP-300

300kg Pallet System

AWC

80kg Work Changer

AF-16

5ton Pallet System

AF-30

20ton Pallet System

Robot

Flexible Processing

SMART Solution

HWACHEON's smart automation technology provides a one-stop solution that anyone can handle, from setting up to machining efficiently.

Details of the Solution

Smart Automation Solution Carries Out from Setting Up to Machining with a 3D Model

HWACHEON's "Smart Solutions Technology" integrates HWACHEON's long standing machine tool experience with their own proprietary "Optimal Control Technology" providing smart solutions for today's manufacturing industry.

This includes the ability to go from setting up to machining with inputting only a 3D model.

HWACHEON provides the most relevant solutions to adapt to an ever changing manufacturing environment that is gradually becoming unmanned, automated and intelligent.

Product Variation

SMART UaX

Graphite SMART MC

SMART Ua STEEL

Steel Mold SMART MC

H-SMART

HWACHEON HMI System