Machining Centers - D3-5AX

D3-5AX is optimized for mass production based on the acceleration/deceleration feed system designed to minimize the cycle time and an easy access structure for robot and automatic workpiece changer.

Rigid and accurate machining is ensured with a high performance in-house designed spindle. Cooling of the spindle and frames minimizes thermal deformation to ensure high precision during long-time machining.

Hwacheon software installed on the machine improves productivity and precision, provides better machining quality compared to existing 5-axis machining centers.

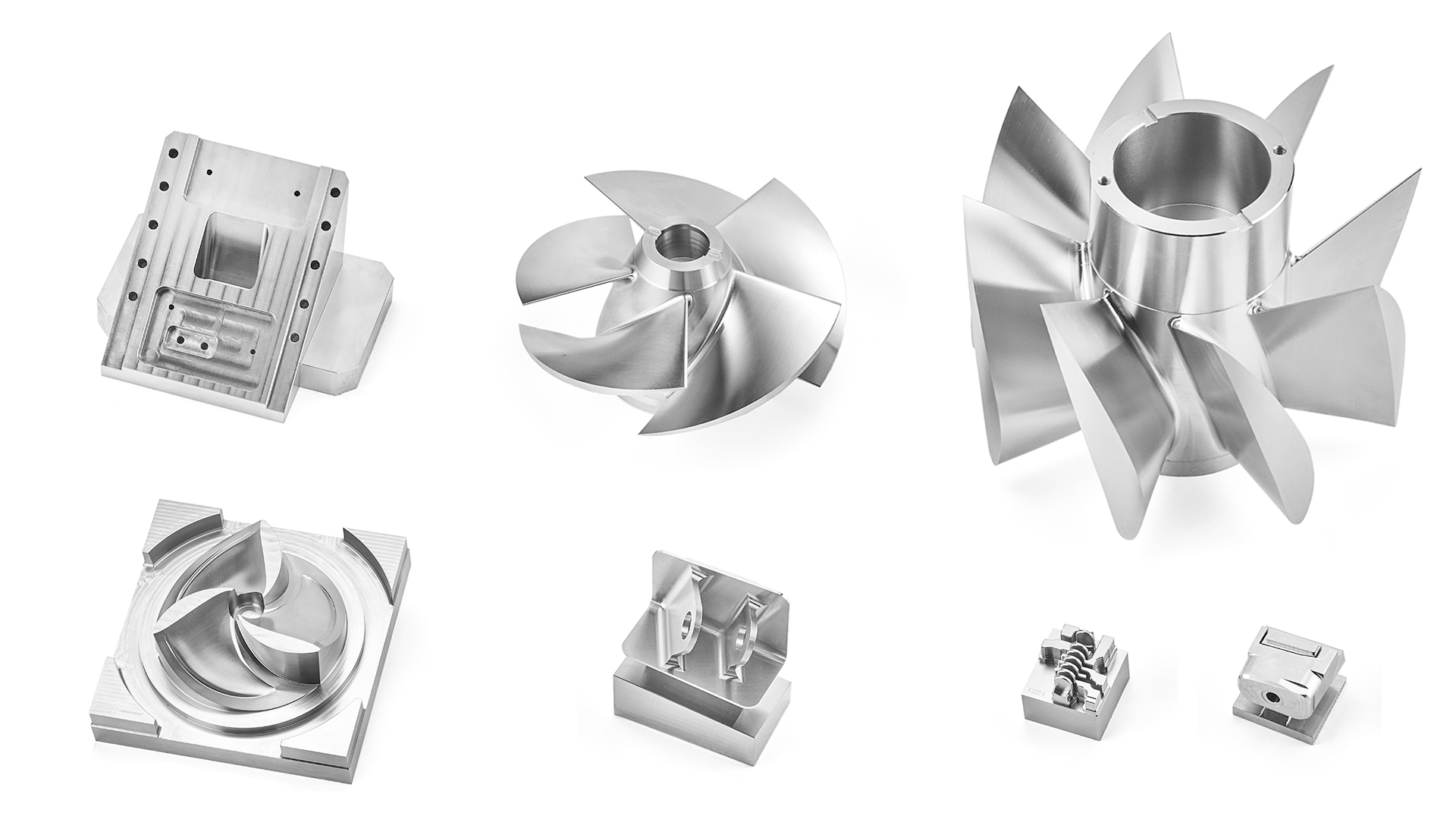

For machining becoming more complex and precise

5-Axis machining drastically reduces cost, time, and error in the setting stage by machining complex shaped parts that require multiple processes in one-setting.It also greatly improves productivity and machining quality by minimizing tool length, maintaining optimal cutting speed, and using side and bottom surfaces of the tool.

Reasonable 5-Axis Machining Solution

Selectable “Simultaneous 5-Axis”, “4+1 Axis” options

A standard 5-Axis is “Simultaneous 5-Axis” in which 5 axes operate simultaneously which is relatively expensive. However, most 5-Axis workpieces can be done with “4+1 Axis”

In D2-5AX, customers may choose between “Simultaneous 5-Axis” and “4+1 Axis” based on their best cost-effectiveness needs.

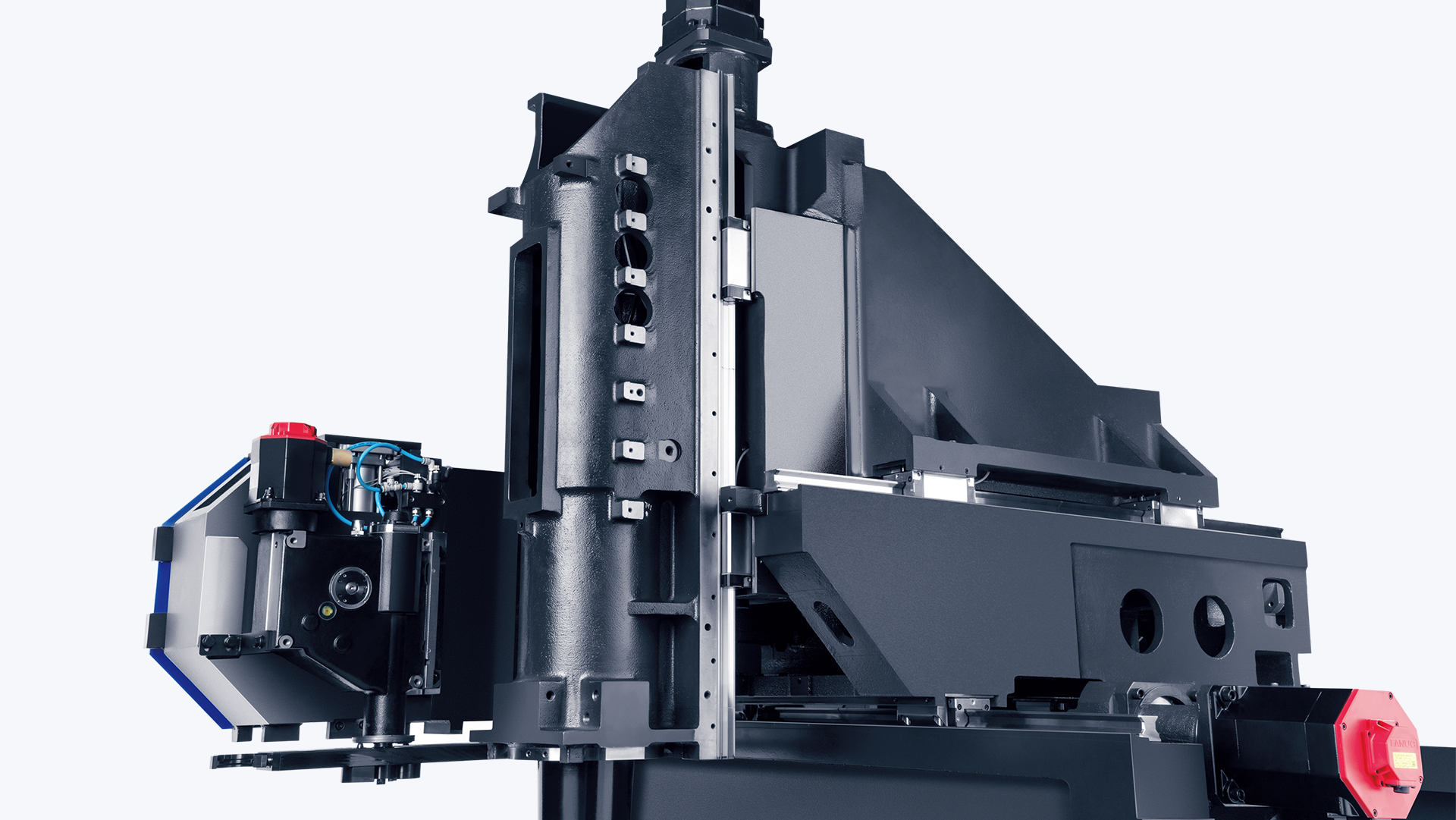

Stable and rapid feed system

Satisfying Speed and Rigidity

For high productivity, it is necessary to have a rapid feed system, but if the frame structure cannot support the feed system, the rigidity of the machine will be weakened, affecting the machining quality.

D2-5AX secures machining stability through Hwacehon’s own casting technology developed for more than half a century and a stable base, column frame, and gantry structure made of the best raw materials, and greatly shortens non-cutting time with very fast acceleration/deceleration performance.

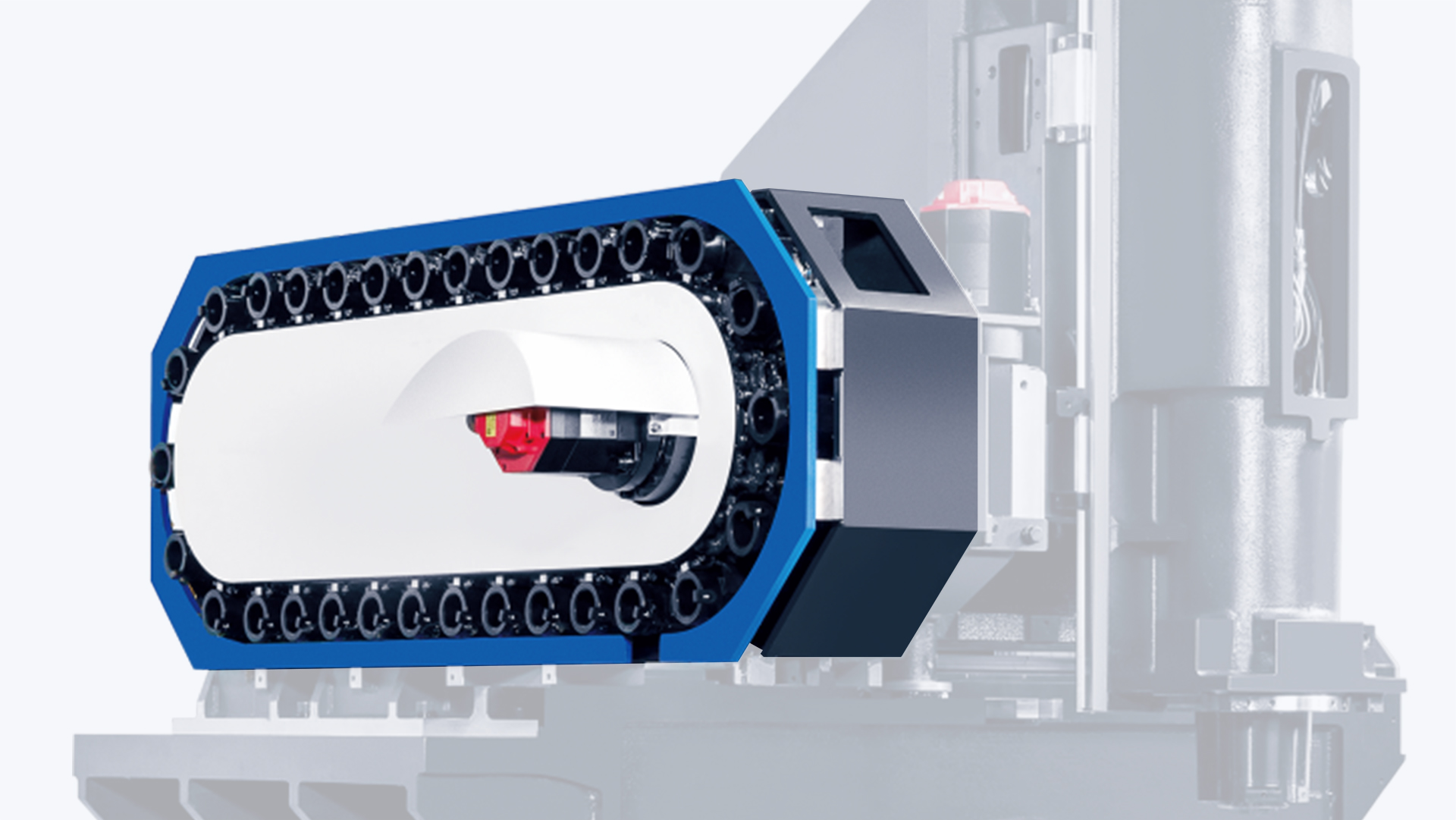

Various Magazine Types

Various types of tools

Sufficient number of tools

Are you still hesitant about 5-Axis Machining?

‘First-time’ is difficult for everyone

Although there are clear advantages of 5-Axis machining, purchasing a 5-Axis machine for the first-time may be a big challenge. Machining methods, cost, tool selection, and operation methods may not be familiar.

Hwacheon can be your strong partner who understands the reasons for your hesitation and willing to offer optimal solutions. We do not only provide excellent machines, but also suggest the most suitable model for the customer's exact workpiece. Hwacheon's machining experts conduct tests for your workpiece and check the actual machining quality, and suggests optimal machining path and tools. Of course, training on machine and software are done as well.

| Item | D3-5AX | ||||

|---|---|---|---|---|---|

| 12K | 14K | 20K | 24K | ||

| Travel | |||||

| X-axis Stroke | mm | 800 | 800 | 800 | 800 |

| Y-axis Stroke | mm | 650 | 650 | 650 | 650 |

| Z-axis Stroke | mm | 575 | 575 | 575 | 575 |

| B-axis Tilting Angle | deg | -30 ~ +110 | -30 ~ +110 | -30 ~ +110 | -30 ~ +110 |

| C-axis Rotation Angle | deg | 360 | 360 | 360 | 360 |

| Distance from Table Surface to Spindle Gauge Plane |

mm | 215 ~ 790 | 215 ~ 790 | 215 ~ 790 | 215 ~ 790 |

| Distance from X-axis guide Top Surface to the center of the spindle |

mm | 193 | 193 | 193 | 193 |

| Table | |||||

| Working Surface | mm | Ø800 | Ø800 | Ø800 | Ø800 |

| Table Loading Capacity | kgf | 600 | 600 | 600 | 600 |

| Table Surface Configuration (T slots W x P – No. of slots) |

mm | 18 x 80 / 5ea | 18 x 80 / 5ea | 18 x 80 / 5ea | 18 x 80 / 5ea |

| Spindle | |||||

| Max Spindle Speed | rpm | 12,000 | 14,000 | 20,000 | 24,000 |

| Spindle Motor | kW | 37 / 18.5 | 37 / 22 | 37 / 18.5 | 37 / 18.5 |

| Type of Spindle Taper Hole | - | BBT-40 | BBT-40 | BBT-40 | BBT-40 |

| Spindle Bearing Inner Diameter | mm | Ø70 | Ø70 | Ø70 | Ø70 |

| Type of Spindle | - | Built-in Motor | Built-in Motor | Built-in Motor | Built-in Motor |

| Method of Spindle Lubrication | - | Grease | Oil-jet | Oil-jet | Oil-jet |

| Method of Spindle Cooling | - | Jacket Cooling (Oil Cooler) |

Jacket Cooling (Oil Cooler) |

Jacket Cooling (Oil Cooler) |

Jacket Cooling (Oil Cooler) |

| Feedrate | |||||

| Rapid Traverse (X / Y / Z) |

m/min | 30 / 30 / 30 | 30 / 30 / 30 | 30 / 30 / 30 | 30 / 30 / 30 |

| Rapid Traverse (B / C) |

rpm | 25 / 25 | 25 / 25 | 25 / 25 | 25 / 25 |

| Motor | |||||

| Servo Motor (X / Y / Z) |

kW | 7 / 4 / 4 | 7 / 4 / 4 | 7 / 4 / 4 | 7 / 4 / 4 |

| Servo Motor (B / C) |

kW | 14.8 / 20 | 14.8 / 20 | 14.8 / 20 | 14.8 / 20 |

| Coolant Motor (Spindle / Chip Flushing) |

kW | 0.6 / 0.6 | 0.6 / 0.6 | 0.6 / 0.6 | 0.6 / 0.6 |

| Spindle Cooler (50 / 60 Hz) |

kW | 2.8 / 3.2 | 2.8 / 3.2 | 2.8 / 3.2 | 2.8 / 3.2 |

| ATC | |||||

| Type of Tool Shank | - | BBT-40 (Opt.: CAT-40 / HSK-A63 / SK-40) |

BBT-40 (Opt.: CAT-40 / HSK-A63 / SK-40) |

BBT-40 (Opt.: CAT-40 / HSK-A63 / SK-40) |

HSK-A63 |

| Type of Pull Stud | - | MAS P40T-1 (45°) | MAS P40T-1 (45˚) | MAS P40T-1 (45°) | MAS P40T-1 (45°) |

| Tool Storage Capacity | ea | 30 (Opt.: 40, 60) |

30 (Opt.: 40, 60) |

30 (Opt.: 40, 60) |

30 (Opt.: 40, 60) |

| Max. Tool Diameter (with / without Adjacent Tools) |

mm | Ø80 / Ø130 | Ø80 / Ø130 | Ø80 / Ø130 | Ø80 / Ø130 |

| Max. Tool Length | mm | 300 | 300 | 300 | 300 |

| Max. Tool Weight | kgf | 8 | 8 | 8 | 8 |

| Method of Tool Selection | - | Memory Random | Memory Random | Memory Random | Memory Random |

| Power Sources | |||||

| Electric Power Supply | kVA | 70 | 70 | 70 | 70 |

| Compressed Air Supply (Pressure) | - | 0.5 ~ 0.7 | 0.5 ~ 0.7 | 0.5 ~ 0.7 | 0.5 ~ 0.7 |

| Tank Capacity | |||||

| Spindle Cooling / Lubrication | ℓ | 50 / 6 | 50 / 6 | 50 / 6 | 50 / 6 |

| Coolant | ℓ | 528.5 | 528.5 | 528.5 | 528.5 |

| Machine Size | |||||

| Height | mm | 3,613 | 3,613 | 3,613 | 3,613 |

| Floor Space (L x W) |

mm | 4,602 X 4,022 | 4,602 X 4,022 | 4,602 X 4,022 | 4,602 X 4,022 |

| Weight | kgf | 15,580 | 15,580 | 15,580 | 15,580 |

| NC System | - | Fanuc 0i-MF Plus (Opt.: Fanuc 31i-B5 Plus) |

Fanuc 0i-MF Plus (Opt.: Fanuc 31i-B5 Plus) |

Fanuc 0i-MF Plus (Opt.: Fanuc 31i-B5 Plus) |

Fanuc 0i-MF Plus (Opt.: Fanuc 31i-B5 Plus) |

-

As an innovation leader in the industry with more than 7,000 employees

-

On the following pages you can obtain information about the nume